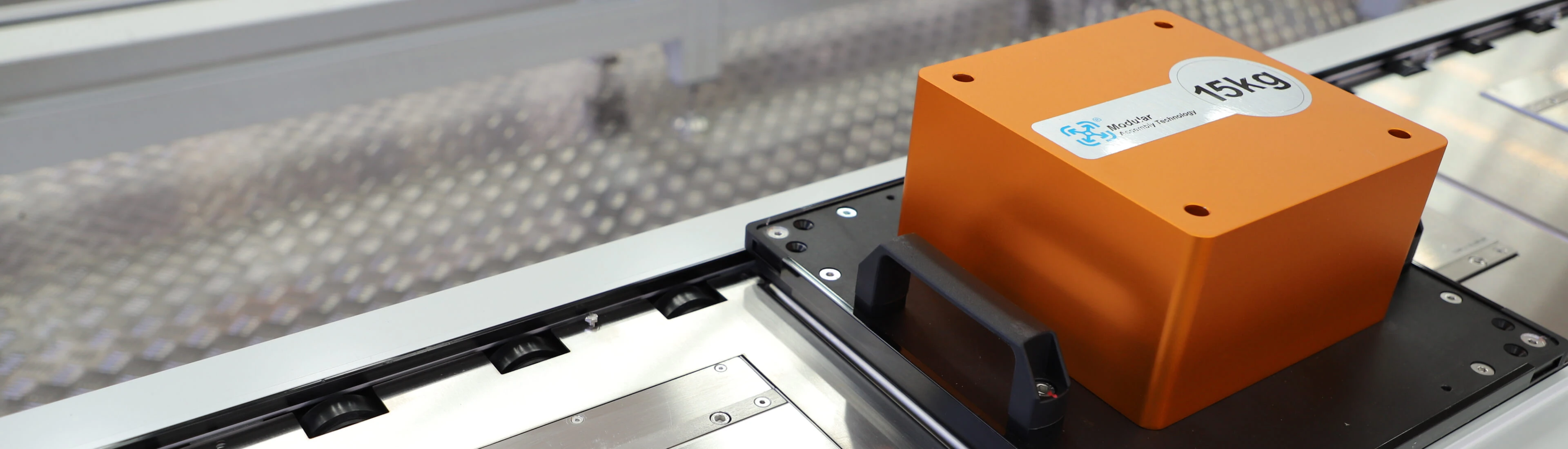

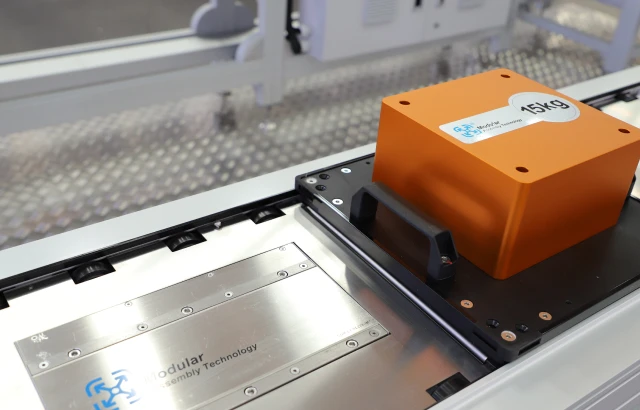

Product Introduction-High-speed Intelligent Roller Transfer System

Innovative products such as High-speed Intelligent Roller Transfer System use multiple brushless reduction motors to achieve segmented start stop control, which increases the number of motor reducers used and reduces the unit price compared to existing products; The hybrid high-speed roller conveyor system is the first of its kind in the industry, combining the advantages of high speed, high precision, high cleanliness, flexibility, low energy consumption, and low cost.