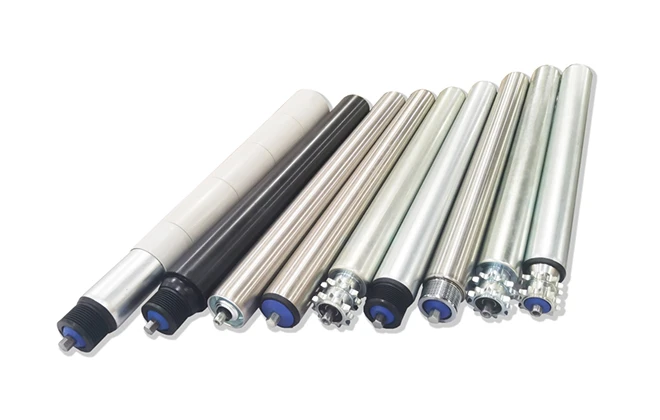

Product Introduction-Conveyor rollers

Conveyor rollers: can be divided into non powered conveyor rollers, powered conveyor rollers, adjustable accumulation power conveyor rollers, cone conveyor rollers, etc., and are one of the main conveying media of conveying equipment.